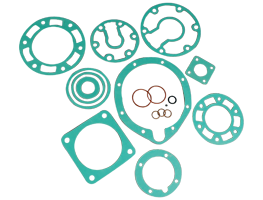

Teflon® Encapsulated O-Rings

Many other sizes available! Custom requests welcome - call now

Call SVI today for Quality American-Made Teflon® Encapsulated O-Rings!

Encapsulated O-rings are o-rings consisting of a seamless and uniform Teflon® FEP/PFA encapsulation/jacket which completely encloses a core material of either silicone or Viton® elastomers. The combination of these components creates an o-ring that is virtually chemically inert and compression set resistant for use in harsh sealing environments.

FEATURES:

- High Chemical Resistance: Chemical attack and swelling are the primary causes of O-Ring failure. Encapsulated o-rings from SVI are virtually chemically inert.

- Outperforms Solid PTFE O-Rings: Our American-Made Encapsulated o-rings match the chemical and temperature resistance of solid PTFE O-Rings; encapsulated o-rings possess properties of elasticity and recovery which are crucial in many sealing applications.

- Economical: Encapsulated o-rings from SVI economically and effectively replace Kalrez and other exotic O-Ring compounds. Our encapsulated o-rings will decrease downtime and hence increase profitability wherever corrosive fluids and gases cause premature seal failure.

- Wide Temperature Range: Encapsulated o-rings withstand breakdown caused by industrial solvents and corrosive materials at elevated temperatures from -60° C/-75° F to +205° C/400° F. (See General Specifications)

- Non Stick Surface: Provides easy cleanup of viscous materials.

- Low Coefficient of Friction: .2 on metal. Self-lubricating surface.

- Sanitary: Eliminates contamination of fluids by elastomers. Sterilizable and autoclavable. FDA compliant, USP Class VI compliant, NSF compliance available for specific applications.

- Unlimited Sizes: Available in standard and metric sizes from .059″ cross section x ½” I.D. to virtually unlimited larger sizes.

- Low Compression Set: Consists of either a solid silicone or Viton® core encapsulated in Teflon®* FEP/PFA resin (with .010 to .045 wall depending cross section) which meets or exceeds requirements of L-P389A and ASTM-D-2166. (See technical bulletin).

GENERAL SPECIFICATIONS:

- Encapsulation Material: DuPont Teflon® FEP: Tetraflouroethylene-Hexafluoropropylene. Dupont Teflon PFA: Tetraflouroethylene-Perfluoro (Propyl Vinyl Ether).

- Core Material: Dow Corning Silicone, DuPont Viton® Type A, Viton® GFS elastomers.

- Continuous Service Temperature:

- Teflon FEP Encapsulation with Silicone Core: 400F/204C. to -75F/-60C

- Teflon PFA Encapsulation with Silicone Core: 500F/260C to -75F/-60C

- Teflon FEP Encapsulation with Viton® Core: 300F/149C to -10F/-23C

- Teflon FEP Encapsulation with HT Viton®

- Teflon PFA Encapsulation with HT Viton® Core: 400F/204C to -10F/-23C

- Coefficient of Friction: .1 to .2 on metal surfaces.

- Water Absorption: <0.01.

- Average Total Shore A Hardness:

- 85-90 shore A for solid silicone core.

- 90-95 shore A for solid Viton® core.

- 75-80 shore A for hollow silicone core.

- FDA Compliance: The clear TEFLON® FEP encapsulation of the o-ring complies with part 177 of Title 21 of the Food and Drug Administration’s regulations for safe use as articles or components of articles for producing, manufacturing, processing, preparing, treating, packing, transporting or holding food in accordance with regulation 177.1550.

*Teflon® is Registered Trademark of DuPont.

Check out our brochure for information on the products we offer!

For pricing information or to place an order, please call today: 800-394-2091

Nothing Found, Please Search Again

Important customer information: All names, numbers, symbols and descriptions are used for reference purposes only. It is not implied that any part listed is the product of these manufacturers; however, some parts may be the actual product of these manufacturers. Prices are subject to change without notice.